Why Use SMC’s EX600 Wireless Solution?

Thursday, June 30, 2022 3:31:36 PM America/New_York

Why Use SMC’s EX600 Wireless Solution?

Can you imagine a situation when something breaks and having the ability to look at a screen to find out what is broken and then fix it? Or a solution that eliminates having to troubleshoot cables and connectors to find the broken item? Or even better, not having to worry if you have the correct cable and connector to fix the issue because you are using wireless technology?

This is where SMC’s EX600 wireless solutions comes into play. Even though SMC is known as a pneumatic systems powerhouse, they have been leading the way in the development of wireless communications for controlling and monitoring motion systems. The future is wireless communications and with our industries current supply chain issues, now is the time to consider this innovative technology.

Two Versions

SMC’s wireless solution comes into versions. The EXW1 is a compact and lightweight system. The EXW1 has a wireless base that is 86% smaller than its non-wireless version and weighs 87% less. Why does weight matter? Because without wires, the devices can be placed in unique locations like at the end of a robot or on a section of the machine that moves. The EXW1 has a communication distance of 100 meters and uses CC-Link to communicate.

The SMC EX600-W series is larger but is modular. You can connect up to 9 stations to the digital/analog unit. The EX600-W series uses the Ethernet/IP and PROFINET communication protocols.

The compact EXW1 and the modular EX600-W can combined. But keep in mind that when the two series are combined, the communication speed/response time is limited to the EX600-W’s specifications – 250kps.

SMC Wireless Benefits

-

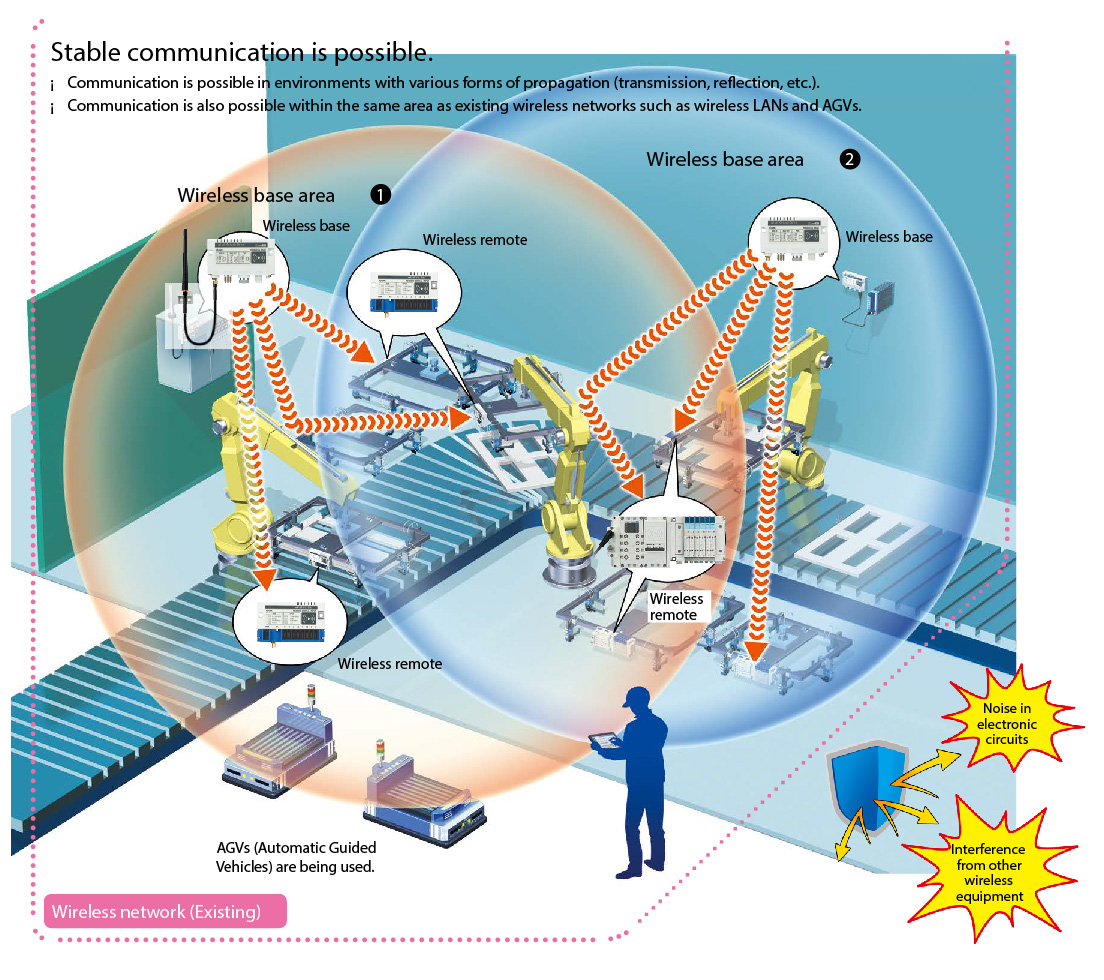

The wireless systems provide communication stability in FA environments. Even if multiple wireless bases are in use in the same communication area, each wireless base can effectively communicate with the remotes with which they are paired. Each wireless base can identify its wireless remotes by their Product ID (P.I.D.). In lay terms, these devices can communicate in environments with various forms of propagation (transmission, reflection, etc.). In addition, these devices can communicate in areas with existing wireless networks such as wireless LANs and AGVs.

-

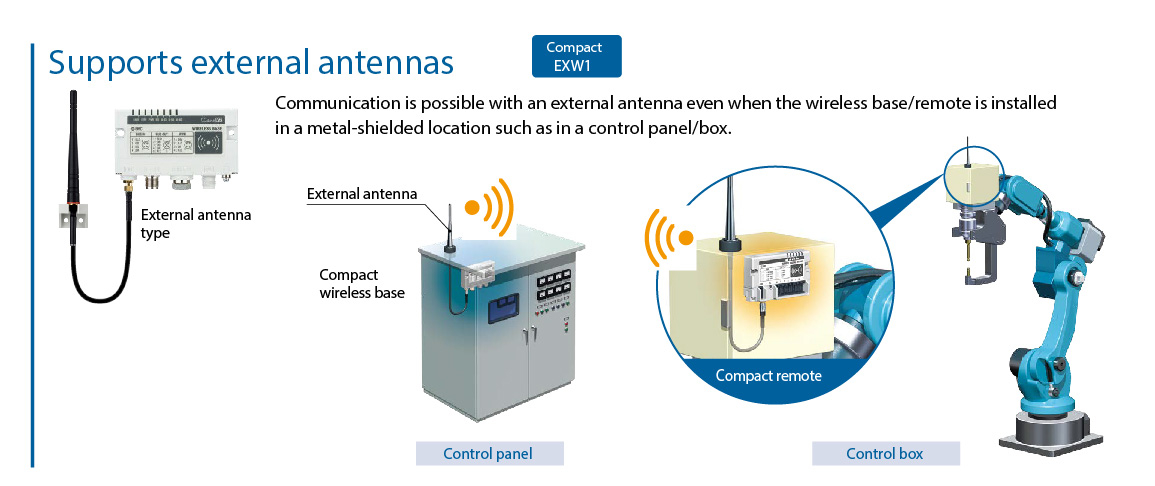

SMC’s wireless systems support external antennas. This allows wireless communications with an external antenna even when the wireless base/remote is installed in a metal-shielded location such as in a control panel/box.

-

Frequency hopping/Event communication system. Frequency hopping allows a stable wireless environment to be established using an original protocol which is not affected by interference. Event communication is performed only when there is a variation in the information, thereby suppressing the frequency of radio wave output in wireless communication and reducing interference with other wireless devices.

-

F.C.S (Frequency Channel Select) function supported. This is a function that allows for the selection of the frequency channel to be hopped to via frequency hopping. When the frequency used by wireless LANs, AGV, or other wireless devices is known, selecting a different frequency channel will allow for hopping only to the selected frequency channel, thereby reducing communication collisions with other wireless devices and stabilizing communication.

-

High security using encryption. Unauthorized access from outside is prevented by using data encryption.

-

Wiring material cost and installation can be reduced. To put this into perspective, wireless base unit communicating with 15 remote units will require one communication line and wire connector from the PLC. A wired system communicating with 15 units will require one communication line and 14 additional lines to the additional 14 units (29 wire connectors/endpoints).

-

Interchangeability maintained. An existing SI unit can be replaced with a wireless unit.

Where can you use the SMC Wireless solution?

Where can you use the SMC Wireless solution?

-

Tool Changing - the wireless solution removes communication cables necessary for moving parts.

-

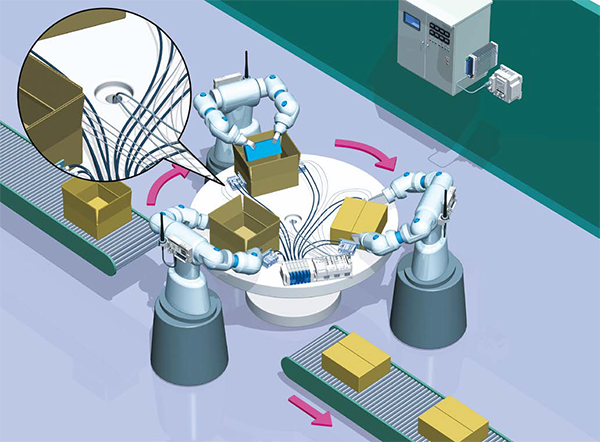

Rotary Tables - the wireless solution minimizes disconnection risk and smaller diameter communication cable/tubing can be used on the machine.

-

Blocking of radio waves – Communication is possible by placing the external antenna outside the control panel when the unit is installed in a metal box, etc.

Reach out to your local Scott Equipment Company Account Manager to learn more about this exciting recent technology.