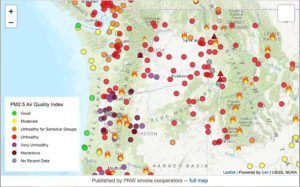

Smoke from a wildfire in the Cascade foothills blew into the Yakima Valley for most of September, but most of the region’s wine industry probably won’t suffer any negative consequences from the smoke.

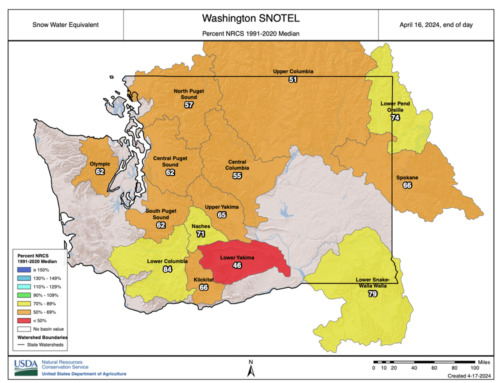

That’s the take from Washington State University’s Tom Collins, who collected data from a network of smoke sensors installed in the region’s vineyards. Comparing that data to the level of smoke exposure he knows it takes to trigger damage in his own experiments, he thinks the exposure stayed below risk thresholds in most of the region.

Wildfire smoke, which now seems like a hallmark of late summer in the West, poses a serious threat to human health and to wine grapes, which can absorb smoke compounds that may taint the resulting wines. But the air quality monitors used to track the human health risk from smoke don’t accurately reflect the risk to grapes and wine.

“The sensors are in Yakima and Sunnyside,” Collins said, two towns in valleys with vineyards on the surrounding slopes, such as WSU’s Roza vineyard outside Prosser where Good Fruit Grower visited during his smoke trials. “They aren’t going to be able to tell us what we need to know out here.”

Bringing smoke sensors to vineyards and developing models to understand how smoke moves in the landscape will help the wine industry assess smoke risk, Collins said.

Right now, the wine industry faces too much “gray area” around the impacts of smoke, according to Elizabeth Tomasino, a wine science professor at Oregon State University. Of the 2020 vintage, she said, “I’m sure some people picked grapes they shouldn’t have, and some people didn’t pick grapes they should have. I’m sure some people dumped product they didn’t need to.”

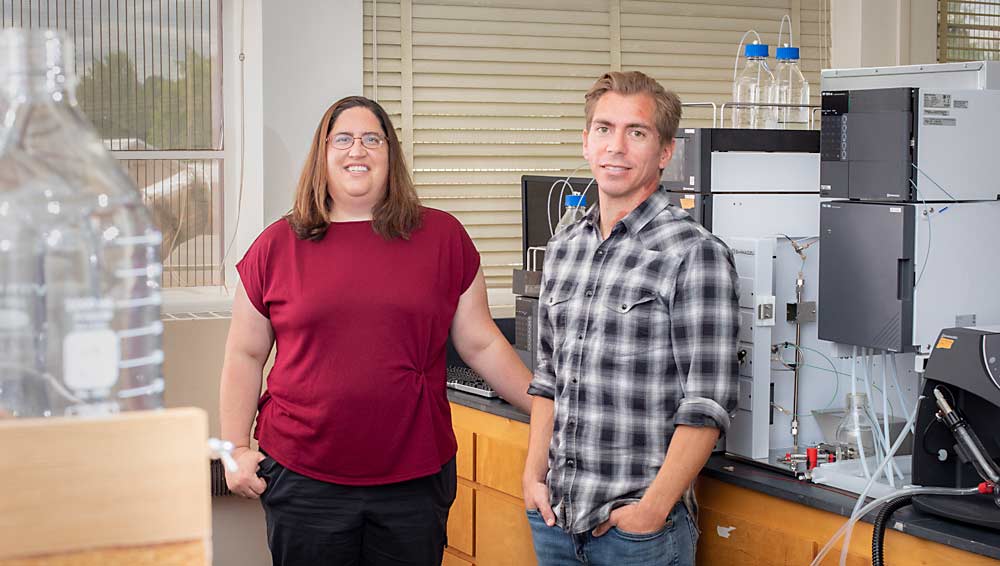

Tomasino and Collins (along with California collaborators) lead the West Coast Smoke Exposure Task Force, an effort linking research and industry together to develop tools to manage the threat from smoke. Research underway across the West aims to reduce that gray area, giving growers and wineries more tools for understanding smoke exposure risk in the vineyard and the juice.

Smoke in the air

Collins set up his first smoker in WSU’s Prosser-area research vineyard in 2016, with support from the Washington wine industry, and that was a little ahead of its time. In the years since, smoke impacts have become an undeniably hot topic, pardon the pun.

Over the years, he’s learned that fresh smoke has the most impact — compared to that blown in from across the region — and the smallest particles are the ones that matter for grape exposure.

That’s why Collins was eager to connect with Scott Waller, who has spent several years working to develop a low-cost wildfire smoke sensor that could help firefighting crews monitor air quality in real time. Waller’s tech company, Thingy IoT, focuses on designing low-cost, low-power connectivity systems for sensors such as weather stations. In 2020, a wine grape growing customer suggested that his smoke sensor might find a home in vineyards desperate to track smoke.

This summer, inside the hoop house trapping smoke with heavy shade cloth, the $3,000 Thingy:AQ sensor collected data against a $40,000 Environmental Protection Agency reference monitor, an approach which Waller said is validating his sensor.

“The numbers have been really, really good, like 98 percent,” he said. While the EPA sensor collects smoke particles on filters that need to be changed every hour and weighed in a lab, Waller’s approach transmits data across a telemetry network he also installs.

“It’s basically a little laser that bounces a beam of light to estimate how many particles are in the chamber at a time, so it can give you particle size and mass,” he said. He’s testing his technology with the U.S. Forest Service and the EPA, and in 2021 he installed about 50 sensors in wine producing areas, in collaboration with researchers and growers.

Some growers will want a local smoke sensor in the vineyard, Collins said, although there are some concerns about sharing that data. He’s also collaborating with atmospheric scientists at WSU to use the smoke monitoring data to build regional models of smoke risks.

“This is the beginning of understanding how smoke moves across the landscape during these events,” Collins said. “Smoke will follow cold air, it will settle (in valleys) but it can also form bands that stream overhead. We saw that this summer.”

The fuel source also matters: Collins has shown that burning sagebrush and rabbitbrush, which surround many Eastern Washington vineyards, result in very different flavors of smoke taint, if you will, than does a forest fire burning conifer trees on the slopes of the Cascades.

“When you burn rabbitbrush, the smoke is horrendous,” he said. This year, to simplify his research trials, he used standard smoker pellets — the “winemaker’s blend,” in a mark of extreme irony — but next year plans to purchase a pellet maker so that he can test different fuel sources with the safety of the pellet approach.

Another piece of technology on loan for the 2021 experiments measures the variation in volatile compounds in the smoke.

“New tools will help us get a better handle on what’s in the smoke,” Collins said. “It’s a complicated process in terms of what’s in the smoke and then all the other factors that go into whether it has an impact: the age of the smoke, the fuel source, the temperature, the humidity and the topography.”

Smoke in the wine

When it comes to smoke testing, the wine industry has three primary needs: reliable testing capacity, improved tests that capture more compounds involved, and sensory thresholds that translate chemical analysis to what wine drinkers perceive and what they dislike, Tomasino said.

The Oregon State team is at work on all those objectives.

With over $2.5 million from state lawmakers, OSU began setting up a new smoke testing lab in 2021 to provide more capacity to the industry next year. That will free up Tomasino’s lab to focus more on research to improve testing.

At this point, testing labs look for a few key markers of smoke exposure, such as guaiacol and 1-methyl guaiacol, she said. But those “free markers” that are easy to test for don’t always correlate strongly with sensory perception of smoke taint. More smoke compounds are bound up with sugars and released in wine over time. There are dozens of such compounds to examine and test for, but labs need access to reference standards so that they know what they are looking for and can focus on those standards that best predict smoke taint.

With new lab equipment and a new chemist on board — postdoctoral researcher Darrell Cole Cerrato — and the data gleaned from thousands of samples submitted last year when the Oregon wine industry faced massive smoke events, Tomasino said the team is making progress on identifying which smoke markers can best predict tainted grapes.

Couple that with her work in sensory perception to translate the lab test results to taste thresholds so “people know what the numbers mean,” she said, “and we’ll be able to greatly shorten the ‘I don’t know’ gray area.”

After joining the team in 2020, Cerrato proposed another idea: using a chemical tag to trace smoke from the burning fuel source to the wine analysis.

So, the “cold, hard analytical chemist” found himself setting up an experiment in the greenhouse. He grew barley, chosen for its rapid growth, while exposing it to an isotope of carbon, C-13, that has an extra neutron. Then, he dried the barley and chopped it up to use as a fuel source to smoke grapes in a micro-version of Collins’ approach.

Once the smoked grapes are made into wine, he will analyze samples in the lab.

“We want to explore if and what chemicals have carbon-13, because the only way it gets into the grape is via the smoke,” Cerrato said.

While the past few seasons have been difficult for wineries and growers facing smoke uncertainty, it’s providing a lot of data to advance all aspects of the research needed.

“It’s an exciting time,” Tomasino said. “The science is snowballing.”

—by Kate Prengaman

Leave A Comment